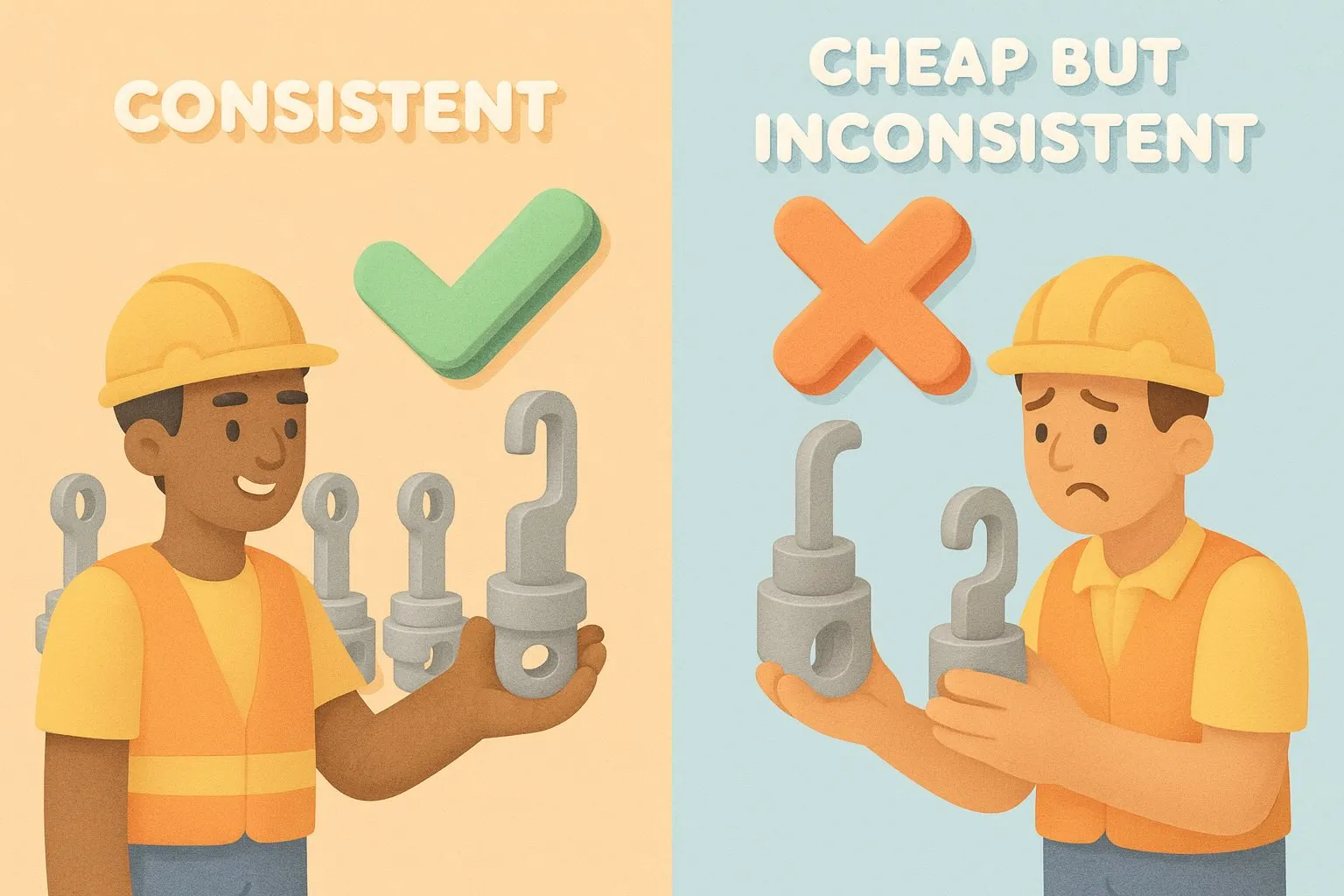

Why Consistency Matters More Than Price in Manufacturing

When sourcing manufactured parts, the temptation is always there: pick the lowest bid, shave a few dollars off the budget, and move on. But anyone who has been through multiple prototyping cycles—or worse, a failed product launch—knows that chasing the cheapest price often leads to the most expensive outcome.

The hidden factor at play isn’t cost per part. It’s consistency.

The Hidden Cost of Cheap Parts

Imagine this: your first batch of parts fits perfectly. You’re excited, testing goes well, and you’re ready to order the next batch. But when the new shipment arrives, suddenly holes are misaligned, threads don’t match, and tolerances are out of spec.

The design didn’t change. What changed was the shop.

Those “savings” on paper have now ballooned into rework, delays, expedited shipping fees, and lost time with your customer. The truth is that a few cents saved per part can cost weeks—or even months—of momentum.

The Problem With “Lowest Bid Wins” Platforms

Many large manufacturing marketplaces operate on a simple formula: every order gets routed to whoever is cheapest at that moment. It sounds efficient, but it introduces a major flaw—randomness.

One order might go to Shop A, the next to Shop B, and the third to Shop C. Each has different machines, different operators, and different quality processes. Even if each shop is good on its own, there’s no guarantee they’ll produce interchangeable parts.

For engineers who need repeatability, this “auction” model is a gamble.

Why Consistency = Trust

Consistency isn’t just about parts being the same size. It’s about:

- Predictability: You know the next order will perform like the last.

- Efficiency: Less time spent re-inspecting and re-qualifying parts.

- Confidence: Trust that your design won’t be undermined by manufacturing variability.

When engineers can rely on consistency, they move faster, make bolder design decisions, and deliver products with confidence.

The True Cost of Inconsistency

Every time parts come back different, the ripple effects are huge:

- Rework and scrap eat into margins.

- Missed deadlines slow down launches.

- Extra inspections drain engineering time.

- Customer trust erodes when reliability slips.

The irony is that paying a little more for a consistent shop usually saves money in the long run.

How Ziqual Solves This

At Ziqual, we believe engineers deserve more than a roulette wheel for their parts. That’s why we’ve built a model around consistency first:

- Same shop for repeat orders → Your parts come from the same machinists who already know your design.

- Direct communication with machinists → No middleman telephone game; you get clarity straight from the source.

- Digital Nameplate Archive (DNA) → Every part carries a QR code that links to its exact recipe, so reorders are traceable and repeatable.

No hidden markups. No random shop hopping. Just consistent, precise parts you can trust.

Build With Confidence

In manufacturing, consistency is the ultimate cost saver. It means fewer surprises, smoother assemblies, and faster product cycles.

Next time you’re tempted by the lowest price, ask yourself: what’s the true cost if the next batch doesn’t match?

At Ziqual, we make sure that doesn’t happen. Because your parts—and your time—are worth more than gambling on inconsistency.