The Rise of Smart Sensors in CNC Machining

How New Sensor Technologies Are Transforming Precision Manufacturing

In the past, machining relied on operator intuition — the feel of the tool, the sound of the spindle, the smell of burning coolant.

Today, the next generation of machinists is guided by data.

Across the industry, smart sensors are reshaping how CNC machines monitor load, vibration, temperature, and even the tool’s health in real time. These devices make machining smarter, safer, and far more predictable — a critical step toward lights-out automation and true Industry 4.0 integration.

Here’s a look at the latest sensors that machinists are finding genuinely useful on the shop floor.

1. Cutting-Force and Tool-Load Sensors

These sensors measure real-time cutting forces and spindle load.

They use strain gauges or integrated transducers to track how hard the tool is working.

Why machinists love them:

- Detects tool wear and breakage automatically.

- Enables adaptive feed control based on real-time conditions.

- Prevents crashes and scrapped parts.

Learn more at Caron Engineering

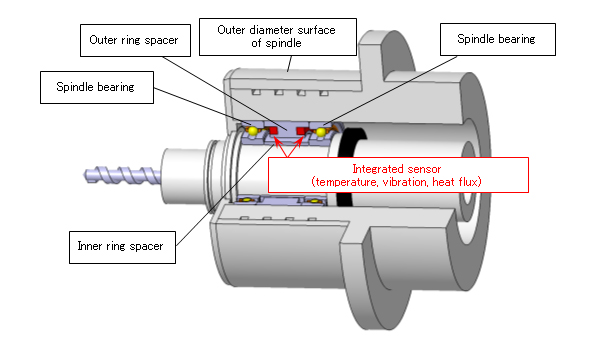

2. Vibration and Acoustic Emission (AE) Sensors

These sensors capture the subtle chatter, resonance, and ultrasonic waves that signal tool or spindle problems.

They can even detect cracks before they’re visible.

Why they matter:

- Early detection of chatter, imbalance, or bearing wear.

- Improves surface finish and part consistency.

- Reduces downtime and spindle rebuild costs.

3. Temperature Sensors

Thermal drift is one of the silent killers of precision.

Modern machines now embed thermocouples and infrared sensors in spindles, toolholders, and coolant lines to monitor and compensate in real time.

Why it’s important:

- Keeps parts within micron tolerances despite heat.

- Detects coolant starvation or overheating early.

- Enables real-time thermal compensation in controls.

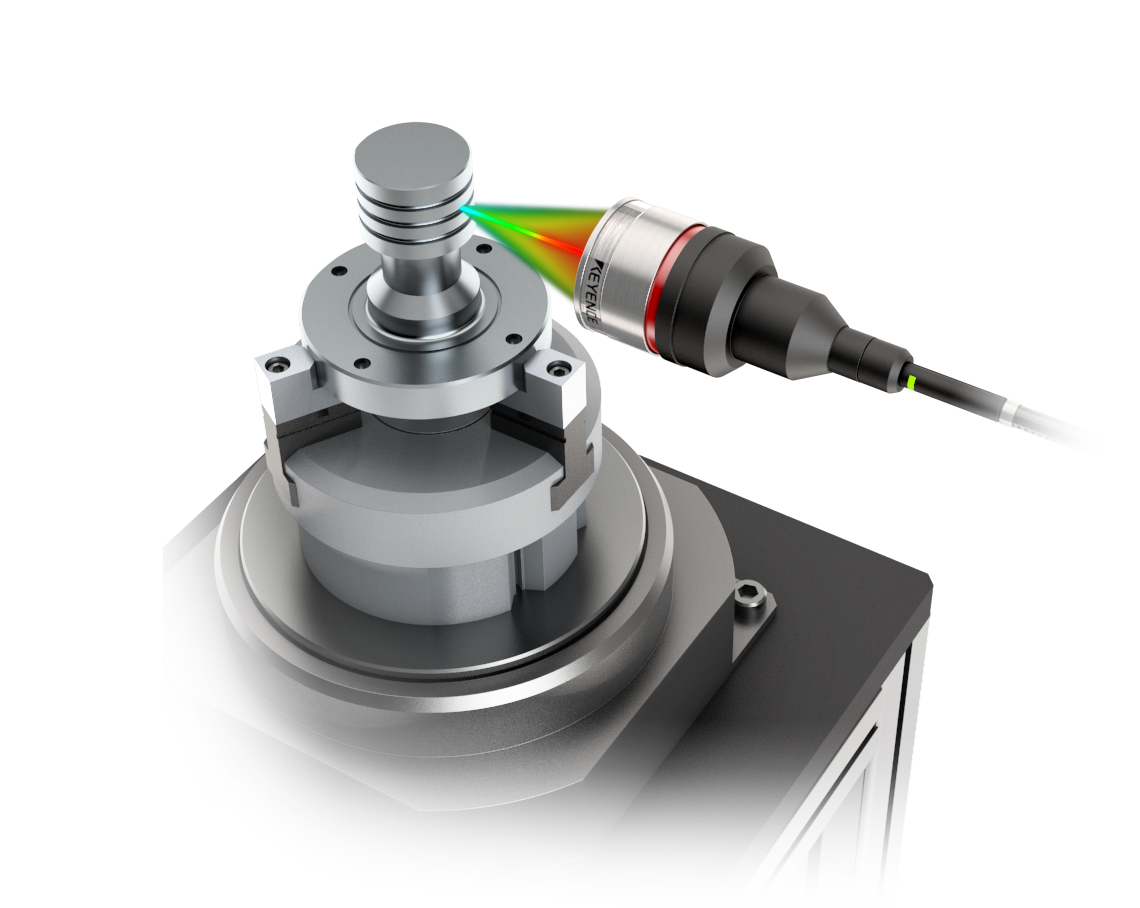

4. High-Resolution Displacement and Position Sensors

Encoders and displacement sensors have existed for decades, but new smart linear encoders offer nanometer-level precision and feedback directly to the controller.

Why machinists use them:

- Reduces cumulative axis error.

- Enables closed-loop control for higher accuracy.

- Critical for aerospace and medical components.

5. Spindle and Tool-Holder Engagement Sensors

A small inductive sensor in the drawbar can prevent big accidents. These sensors confirm tool-holder engagement and measure clamping force.

Why it matters:

- Prevents tool-drop or partial engagement failures.

- Logs spindle cycles for predictive maintenance.

- Adds safety and reliability with minimal retrofit cost.

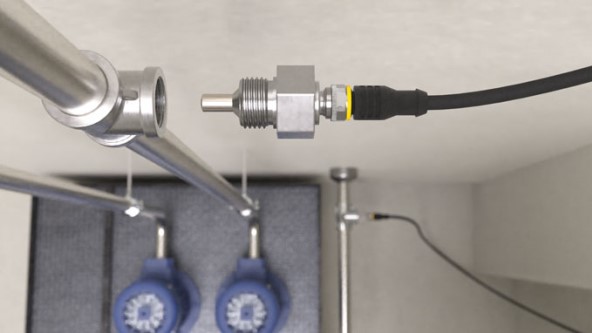

6. Coolant-Flow and Pressure Sensors

Coolant problems cause more tool wear than most machinists realize.

Sensors now track flow rate, pressure, and even contamination.

Why machinists appreciate them:

- Detects clogs or pump failures instantly.

- Ensures constant cooling for consistent finish.

- Enables unattended machining with confidence.

7. Smart IoT-Connected Sensors

This is where sensors meet software.

Newer modules communicate via Ethernet, MQTT, and OPC UA, feeding data into dashboards, edge devices, or cloud systems.

Why it’s a game-changer:

- Enables predictive maintenance and remote monitoring.

- Centralizes data from multiple machines and tools.

- Turns every sensor into a data point for analytics.

8. Gap, Clearance, and Machine-Health Sensors

Eddy-current and capacitive sensors measure tiny displacements in spindles, bearings, or machine frames.

Why shops install them:

- Detects bearing wear and machine looseness early.

- Monitors long-term geometric stability.

- Improves precision in ultra-tight tolerance work.

9. Tool-Wear Detection Sensors

Sensors inside toolholders or spindles measure wear, edge degradation, and micro-chipping.

When combined with AI models, they predict tool life with impressive accuracy.

Why they’re useful:

- Reduces tool costs and scrap.

- Optimizes tool-change intervals.

- Essential for lights-out and high-value machining.

10. Environmental and Structural Sensors

Modern machines track not only themselves but their surroundings.

Ambient temperature, humidity, and even machine-bed strain affect accuracy.

Why machinists are adopting them:

- Detects room-temperature drift that affects tolerances.

- Enables thermal compensation for the entire system.

- Provides valuable long-term performance data.

The Big Picture: Precision Meets Prediction

Sensors aren’t replacing machinists — they’re amplifying intuition with data.

By monitoring the invisible — force, vibration, temperature, and wear — sensors give machinists the power to predict problems before they happen.

For shops aiming to scale, automate, or run overnight, these technologies are no longer optional — they’re the backbone of smart, connected manufacturing.

At Ziqual

We work with machinists and innovators who embrace precision and continuous improvement.

If you’re building your next prototype or production run, Ziqual connects you with machine shops that run smarter, faster, and more predictably — powered by data.

👉 Get your quote today and join the new era of intelligent manufacturing.