When we think about machined parts, the focus is usually on what we can see: clean edges, polished surfaces, precise dimensions. But many of the most important details are invisible to the naked eye — microscopic scratches, surface roughness, or defects smaller than a human hair.

This is where confocal microscopy comes in. Originally developed for biomedical imaging, it’s now a powerful tool in advanced manufacturing, letting us see details that traditional inspection methods miss.

What Is Confocal Microscopy?

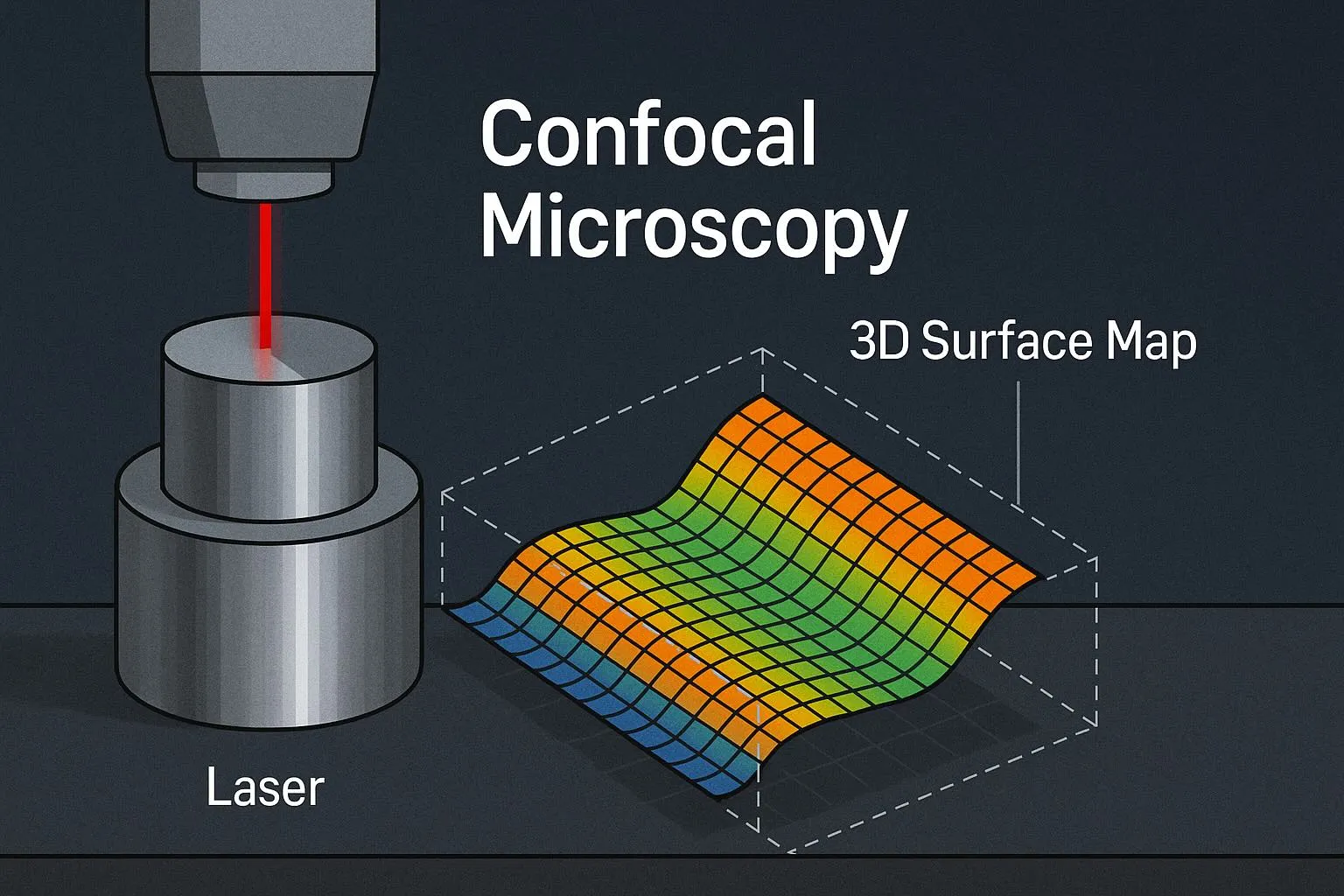

Confocal microscopy uses a focused laser beam that scans across the surface of a part. Unlike a standard optical microscope, it blocks out-of-focus light using a pinhole, capturing only what’s at the exact focal plane. By moving the focus point up and down, it builds a 3D map of the surface.

Think of it like “stacking” razor-sharp images together to reveal fine topography in stunning detail.

Why It Matters for Machined Parts

Confocal microscopy can measure things that matter a lot in precision engineering:

- Surface roughness: Determines how well parts fit together, seal fluids, or reduce friction.

- Micro-cracks: Early-stage cracks invisible to standard inspection can be caught before they grow.

- Step heights & dimensions: Useful for verifying micromachined features or delicate geometries.

- Coatings & films: Thickness and uniformity can be inspected without damaging the part.

Real-World Applications

Confocal microscopy isn’t just academic — it has practical roles across industries:

- Aerospace: Inspecting turbine blades for microscopic wear that could lead to catastrophic failure.

- Medical devices: Ensuring implants or surgical tools have biocompatible surface finishes.

- Optics: Checking lens mounts or reflective surfaces for nanoscale scratches that impact performance.

- Electronics: Verifying microelectromechanical systems (MEMS) or fine connectors.

Advantages Over Other Methods

Compared to other surface inspection tools, confocal microscopy offers:

- Non-contact measurement → no risk of scratching or contaminating the part.

- High resolution → down to nanometer scale.

- 3D mapping → gives a full surface profile, not just a single measurement point.

While techniques like tactile profilometry or scanning electron microscopy (SEM) are useful, confocal microscopy strikes a balance: fast, precise, and non-destructive.

Wrapping Up

At Ziqual, we’re always interested in how advanced metrology tools can improve quality and reliability. Confocal microscopy shows us the invisible world of surfaces — giving engineers confidence that their parts don’t just look right, but perform right.

When tolerances are tight and stakes are high, seeing the invisible makes all the difference.