Metal 3D printing, also known as additive manufacturing, has revolutionized industries ranging from aerospace to medical to automotive. Its ability to create complex geometries, reduce material waste, and shorten production times makes it an appealing choice for innovators and engineers. However, this advanced technology comes with its own set of challenges and considerations. If you’re thinking of integrating metal 3D printing into your projects or business, here are the key factors to evaluate:

1. Understanding the Technology

Metal 3D printing isn’t a one-size-fits-all solution. Various methods exist, each with unique capabilities and limitations:

- Powder Bed Fusion (PBF): Uses lasers or electron beams to fuse metal powder layer by layer. Ideal for detailed, high-strength components.

- Directed Energy Deposition (DED): Deposits metal powder or wire using a heat source, suitable for repairs or adding features to existing parts.

- Binder Jetting: Uses a binder to form parts, which are later sintered. Faster and more cost-effective for high-volume production.

- Material Extrusion: Similar to FDM in polymer printing but uses metal-filled filaments. Great for prototyping.

Understanding the process that aligns with your project’s goals is crucial.

2. Material Selection

Not all metals are 3D-printable, and the choice of material will affect the mechanical properties, cost, and application of the final product. Common materials include:

- Titanium Alloys: Known for high strength-to-weight ratios, ideal for aerospace and medical applications.

- Stainless Steel: Versatile and corrosion-resistant, used in food, medical, and industrial applications.

- Aluminum: Lightweight and heat-resistant, perfect for automotive and aerospace parts.

- Nickel Alloys: Excellent for high-temperature applications, such as turbine components.

Each material has unique printability, shrinkage rates, and post-processing requirements that must be factored in.

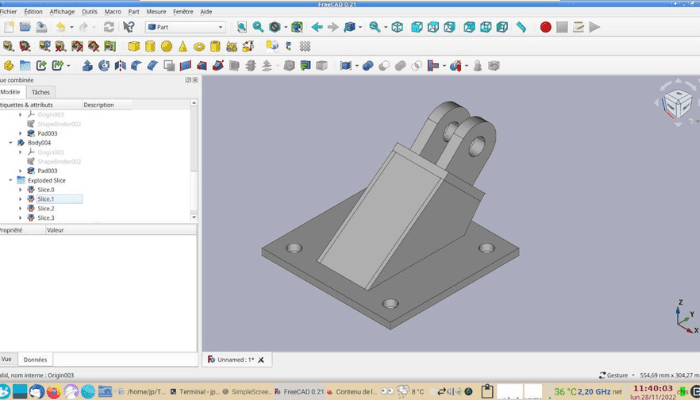

3. Design for Additive Manufacturing (DfAM)

Designing for metal 3D printing is fundamentally different from traditional manufacturing:

- Support Structures: Metal prints often require supports during the printing process to prevent warping or collapse. These must be carefully planned and later removed.

- Complexity vs. Feasibility: While the technology allows intricate geometries, overly ambitious designs can lead to structural weaknesses or failed prints.

- Topology Optimization: Utilize software to reduce weight and improve structural performance, especially in aerospace and automotive components.

Adopting a DfAM mindset can unlock the full potential of metal 3D printing.

4. Cost and Scalability

Metal 3D printing can be expensive, especially for beginners. Costs include:

- Initial Investment: Printers, powders, and post-processing equipment.

- Material Costs: Metal powders are expensive, and some processes have high material wastage rates.

- Operational Costs: Energy consumption, maintenance, and skilled labor can add up.

For small production runs or prototypes, the cost may be justifiable, but for large-scale production, traditional methods like CNC machining or casting might still be more economical.

5. Post-Processing Requirements

Metal 3D printed parts rarely come out of the printer ready to use. Post-processing can involve:

- Heat Treatments: To relieve residual stresses or improve mechanical properties.

- Surface Finishing: Sanding, polishing, or machining to meet aesthetic or functional requirements.

- Support Removal: Manual or automated processes to eliminate support structures.

Understanding the time and effort needed for post-processing is essential when planning production timelines.

6. Quality and Safety

Ensuring consistent quality in metal 3D printing can be challenging:

- Porosity: Improper fusion or contamination can lead to tiny voids, weakening the part.

- Residual Stresses: Cooling rates and thermal gradients can cause internal stresses and distortions.

- Powder Handling: Metal powders are highly reactive and pose explosion or inhalation risks if not handled in a controlled environment.

Investing in quality assurance processes, such as non-destructive testing and X-ray inspections, is critical.

7. Environmental Impact

While metal 3D printing reduces material waste compared to subtractive manufacturing, it’s not inherently eco-friendly:

- Energy Intensity: Laser and electron beam processes consume significant power.

- Powder Recycling: Not all leftover powder can be reused, leading to waste.

- Supply Chain: Metal powder production and transportation have their own carbon footprints.

Consider sustainability when planning your projects, and explore options for recycling and energy-efficient practices.

8. Applications and Trends

The versatility of metal 3D printing has led to groundbreaking innovations:

- Aerospace: Lightweight, complex parts for satellites, rockets, and aircraft.

- Medical: Custom implants and prosthetics tailored to individual patients.

- Automotive: Prototyping and small-batch production of high-performance components.

- Tooling: Rapid production of molds and jigs for manufacturing processes.

Emerging trends, like multi-material printing and AI-driven design optimization, are pushing the boundaries of what’s possible.

Final Thoughts

Metal 3D printing offers immense potential for innovation, but success depends on a clear understanding of its capabilities and limitations. By carefully considering factors like technology selection, cost, design, and quality control, you can harness this powerful tool to create next-generation products.

Whether you’re prototyping intricate designs or scaling production of high-performance parts, metal 3D printing is an investment in the future of manufacturing.

Cover photo source: nexa3d.com