When manufacturing parts, selecting the right aluminum alloy can significantly impact the performance, durability, and cost-effectiveness of your components. With dozens of aluminum alloys available, each with unique properties, it’s important to make an informed decision. Here’s a guide to help you choose the ideal alloy for your application.

Understand the Application Requirements

Start by defining the specific requirements for your part. Consider:

- Mechanical Properties: Do you need high strength, corrosion resistance, or fatigue resistance?

- Operating Environment: Will the part be exposed to high temperatures, moisture, or chemicals?

- Weight Considerations: Is minimizing weight critical to your application?

- Machinability: Will the alloy need to be easy to machine or weld?

- Cost: Are there budget constraints?

Understanding these factors will help you narrow down your options.

Common Aluminum Alloy Series and Their Uses

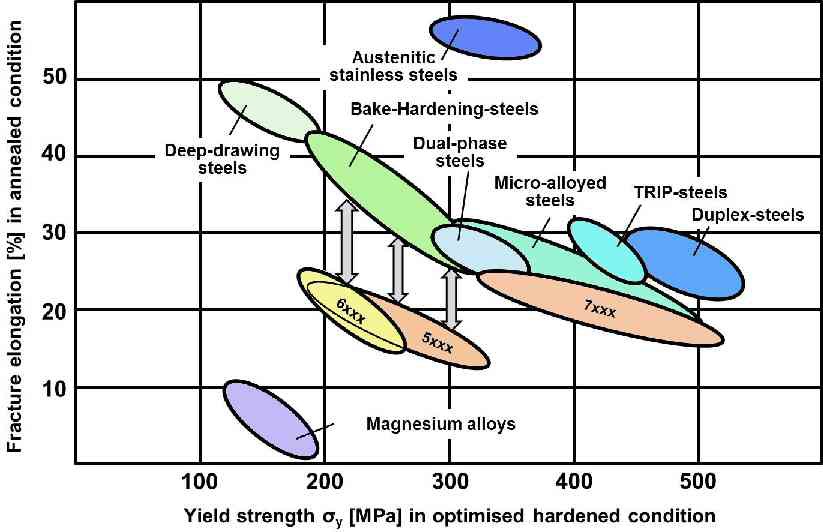

Aluminum alloys are divided into series based on their composition. Here are some of the most common series and their typical applications:

1XXX Series: Pure Aluminum

- Properties: Excellent corrosion resistance, high thermal and electrical conductivity, low strength.

- Applications: Electrical conductors, chemical processing equipment.

2XXX Series: Aluminum-Copper Alloys

- Properties: High strength, less corrosion resistance, typically requires heat treatment.

- Applications: Aerospace components, automotive parts.

3XXX Series: Aluminum-Manganese Alloys

- Properties: Good corrosion resistance, moderate strength.

- Applications: Roofing, siding, cooking utensils.

5XXX Series: Aluminum-Magnesium Alloys

- Properties: Excellent corrosion resistance, moderate-to-high strength, good weldability.

- Applications: Marine parts, pressure vessels, automotive panels.

6XXX Series: Aluminum-Magnesium-Silicon Alloys

- Properties: Good strength, corrosion resistance, excellent machinability.

- Applications: Structural components, pipelines, automotive frames.

7XXX Series: Aluminum-Zinc Alloys

- Properties: Very high strength, less corrosion resistance, often requires heat treatment.

- Applications: Aerospace components, sporting equipment.

Consider Processing Methods

The manufacturing process can influence the choice of alloy. For example:

- Machining: Alloys in the 6XXX series are often preferred due to their excellent machinability.

- Welding: 5XXX and 6XXX series alloys generally offer good weldability.

- Heat Treatment: Alloys in the 2XXX, 6XXX, and 7XXX series can be heat-treated to enhance their properties.

Balance Performance and Cost

High-performance alloys like those in the 7XXX series may provide exceptional strength but can be costly and less corrosion-resistant. Conversely, alloys like the 1XXX and 3XXX series are cost-effective but might not meet demanding mechanical requirements. Evaluate the trade-offs carefully.

Seek Expert Advice

If you’re uncertain about which alloy to choose, consult with a material specialist or your manufacturing partner. Their expertise can help you select the best alloy for your specific needs.

Conclusion

Selecting the right aluminum alloy for your parts is a critical step in ensuring the success of your project. By understanding your application requirements, exploring the properties of different alloy series, and considering the manufacturing process, you can make an informed decision that balances performance, cost, and durability.

Whether you’re designing aerospace components or automotive parts, the right aluminum alloy can make all the difference.

Cover photo source: dierk-raabe.com